Difference between revisions of "3D Printer"

| (20 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

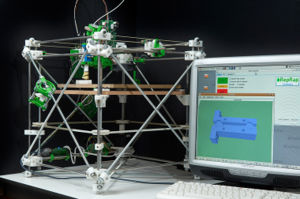

| − | + | [[Image:Reprap-small.jpg|thumb|300px|right|RepRap 3D printer]] | |

| + | '''3D printing''' , also known as ''Rapid Prototyping'' and '''additive manufacturing''', is a technology of creating objects layer-by-layer. It will make it possible for the [[Mars]] settlement to fabricate items from in-situ materials. 3D printers used to depend on highly processed plastics and metals but the field is advancing very fast. 3D printing technology is quickly getting cheaper and faster, as 3D printers are getting available for only a few hundred dollars. Advanced 3d printers may be able to print [[electronics]] with high precision if the sophisticated raw materials for these electronics (such as copper and silicon) can be made available in purified form. | ||

| − | 3D | + | If Martian materials can be used for fabrication, then a single 3D printer can be sent instead of many items, thus saving valuable mass. 3D printers have been tested on the ISS, so in conditions that are more difficult than on Mars. |

| + | |||

| + | NASA has been sponsoring a competition for large scale additive manufacturing to create habitats for a martian base<ref>https://www.nasa.gov/directorates/spacetech/centennial_challenges/3DPHab/index.html</ref>. | ||

| + | |||

| + | ==Self replicating machines== | ||

| + | 3D printers usually operate with a single material, but are made from many different materials. So a self replicating 3D printer (a self replicating machine) would need to be a number of printers, each processing one of the required materials. 3D printers also usually produce parts, rather than entire mechanisms, so self replicating 3D printers would also require a robotic assembler. Most 3D printers also produce parts that do not have the required surface finish and precision for final operations. So some kind of surface finishing tool, such as Computer Numerical Control (CNC) machines, would be required to finish shafts and rolling parts to adequate tolerances. So a Self replicating 3D printer would in fact be more like a small factory, capable or producing each of the different parts of the factory and then assembling them into a second factory. So it might be fairly massive and complex. Such a self replicating machine has been speculated upon for a number of decades and may eventually be produced. See Wikipedia; [[w:Self-replicating_machine#cite_note-40|Self replicating machines]] for extensive references. | ||

| + | |||

| + | ==Speed of operation== | ||

| + | 3D printers are slow (as of 2022) compared to other manufacturing methods such as extrusion machines, presses or rolling mills. However, extensive parallel operations might offset some of the losses in speed, and continuous operation as opposed to discreet assembly might also provide some speed gains. 3d printers can also be used to produce faster machines, creating a more effective factory from the slower original machines. | ||

| + | |||

| + | ==Materials== | ||

| + | Additive manufacturing, as of 2018, can use the following metals<ref>https://www.engineering.com/AdvancedManufacturing/ArticleID/16955/Additive-Manufacturing-Materials-for-Production.aspx</ref>: | ||

| + | |||

| + | *Aluminum | ||

| + | *Cobalt | ||

| + | *Copper | ||

| + | *Inconel | ||

| + | *Nickel | ||

| + | *Precious Metals (Gold, Silver, Platinum) | ||

| + | *Stainless Steel | ||

| + | *Tantalum | ||

| + | *Titanium | ||

| + | *Tool Steel | ||

| + | *Tungsten | ||

| + | |||

| + | As well as the following plastic materials: | ||

| + | |||

| + | *Acetal | ||

| + | *Acrylic | ||

| + | *Acrylonitrile Butadiene Styrene (ABS) | ||

| + | *Acrylonitrile Styrene Acrylate (ASA) | ||

| + | *High Impact Polystyrene (HIPS) | ||

| + | *Nylon | ||

| + | *Polycarbonate (PC) | ||

| + | *Polyether Ether Ketone (PEEK) | ||

| + | *Polyethylene Terephthalate (PET) | ||

| + | *Polyethylene Trimethylene Terephthalate (PETT) | ||

| + | *Polyethylene Yerephthalate Glycol-Modified (PETG) | ||

| + | *Polylactic Acid (PLA) | ||

| + | *Polypropylene (PP) | ||

| + | *Polyvinyl Alcohol (PVA) | ||

| + | *Thermoplastic Elastomer (TPE) | ||

| + | *ULTEM | ||

| + | |||

| + | All the materials required for additive manufacturing are available in-situ on Mars. The following might be the ones the most interesting to develop: | ||

| + | |||

| + | *Steel | ||

| + | *Aluminium | ||

| + | *Plastics | ||

| + | *Concrete and concrete substitutes | ||

| + | *Ceramics | ||

| + | *Silicon | ||

| + | |||

| + | Plastics are not available directly but can be manufactured, using a number of intermediates steps, from atmospheric CO2 and water from the martian regolith. | ||

| + | |||

| + | ==Interwiki== | ||

| + | |||

| + | *{{lunarp|RepRap|RepRap on Lunarpedia}} | ||

| + | |||

| + | ==References== | ||

| + | [[Category:Manufacture]] | ||

| + | <references /> | ||

Latest revision as of 13:15, 12 September 2022

3D printing , also known as Rapid Prototyping and additive manufacturing, is a technology of creating objects layer-by-layer. It will make it possible for the Mars settlement to fabricate items from in-situ materials. 3D printers used to depend on highly processed plastics and metals but the field is advancing very fast. 3D printing technology is quickly getting cheaper and faster, as 3D printers are getting available for only a few hundred dollars. Advanced 3d printers may be able to print electronics with high precision if the sophisticated raw materials for these electronics (such as copper and silicon) can be made available in purified form.

If Martian materials can be used for fabrication, then a single 3D printer can be sent instead of many items, thus saving valuable mass. 3D printers have been tested on the ISS, so in conditions that are more difficult than on Mars.

NASA has been sponsoring a competition for large scale additive manufacturing to create habitats for a martian base[1].

Self replicating machines

3D printers usually operate with a single material, but are made from many different materials. So a self replicating 3D printer (a self replicating machine) would need to be a number of printers, each processing one of the required materials. 3D printers also usually produce parts, rather than entire mechanisms, so self replicating 3D printers would also require a robotic assembler. Most 3D printers also produce parts that do not have the required surface finish and precision for final operations. So some kind of surface finishing tool, such as Computer Numerical Control (CNC) machines, would be required to finish shafts and rolling parts to adequate tolerances. So a Self replicating 3D printer would in fact be more like a small factory, capable or producing each of the different parts of the factory and then assembling them into a second factory. So it might be fairly massive and complex. Such a self replicating machine has been speculated upon for a number of decades and may eventually be produced. See Wikipedia; Self replicating machines for extensive references.

Speed of operation

3D printers are slow (as of 2022) compared to other manufacturing methods such as extrusion machines, presses or rolling mills. However, extensive parallel operations might offset some of the losses in speed, and continuous operation as opposed to discreet assembly might also provide some speed gains. 3d printers can also be used to produce faster machines, creating a more effective factory from the slower original machines.

Materials

Additive manufacturing, as of 2018, can use the following metals[2]:

- Aluminum

- Cobalt

- Copper

- Inconel

- Nickel

- Precious Metals (Gold, Silver, Platinum)

- Stainless Steel

- Tantalum

- Titanium

- Tool Steel

- Tungsten

As well as the following plastic materials:

- Acetal

- Acrylic

- Acrylonitrile Butadiene Styrene (ABS)

- Acrylonitrile Styrene Acrylate (ASA)

- High Impact Polystyrene (HIPS)

- Nylon

- Polycarbonate (PC)

- Polyether Ether Ketone (PEEK)

- Polyethylene Terephthalate (PET)

- Polyethylene Trimethylene Terephthalate (PETT)

- Polyethylene Yerephthalate Glycol-Modified (PETG)

- Polylactic Acid (PLA)

- Polypropylene (PP)

- Polyvinyl Alcohol (PVA)

- Thermoplastic Elastomer (TPE)

- ULTEM

All the materials required for additive manufacturing are available in-situ on Mars. The following might be the ones the most interesting to develop:

- Steel

- Aluminium

- Plastics

- Concrete and concrete substitutes

- Ceramics

- Silicon

Plastics are not available directly but can be manufactured, using a number of intermediates steps, from atmospheric CO2 and water from the martian regolith.