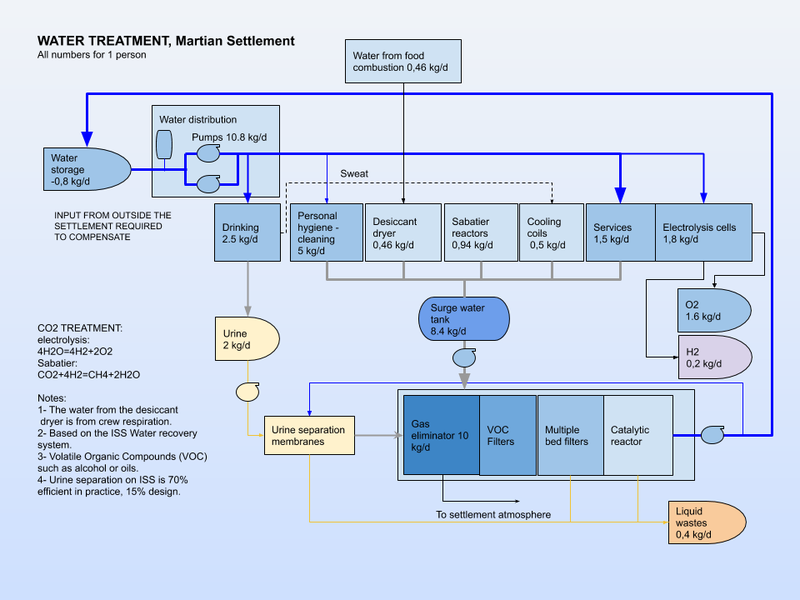

Potable water treatment

Potable water treatment facilities are an essential requirement for a Martian settlement. A number of the following processes may be required, depending on the source of the water. Some industrial processes will produce clean water than can be used in a potable water system. Waste water treatment facilities are very similar to water treatment facilities, but will treat more heavily contaminated water. In a closed loop system, the cleaned waste water is returned to the potable water treatment system for re-use. The water distribution system links the two ends of the water infrastructure.

Martian water contaminants

Salts, sand and hydrated minerals. Minerals (Ca,Mg,Fe) Primary contaminants from the martian environment and secondary contaminants from human use.

Water hardness. perchlorate.

Water treatment processes

- Reverse osmosis (perchlorates,Ca,Mg)

- Ion exchange resins (perchlorates, calcium, magnesium)

- Sand filtration (suspended solids)

- Chlorination (biological contamination, pathogens)

- Ozonation (biological contamination, pathogens)

- Activated charcoal (organics, Volatile Organic Compounds)

- PH balancing

- Electroconductivity adjustment

- Flocculation (suspended particles)

- Desalination (salts, Ca,Mg)

- Evaporation

- Organic solids removal

Water treatment plant

The first water treatment plants will be packaged units provided from Earth. These types of units are already produced on Earth for buildings and communities isolated from the larger centralized water treatment plants available for towns and cities.

TSSE

Temperature Swing Solvent Extraction(TSSE)[1]is a process for removing impurities from water using a solvent at various temperatures. It works on the basis that the amount of water that a solvent can hold changes with temperature, so by "swing"ing the temperature of the solvent, it can extract water from brine and deposit it elsewhere. This process is useful because it requires only low grade waste heat to run and easily produced industrial solvents, rather than needing high pressure pumps and custom membranes in a reverse osmosis system. The primary drawback is that without a final reverse osmosis step, the water may contain traces of solvent. A two phase system utilizing Diisopropylamine (DIPA) and diethyl ether (Eth) was suggested to resolve this issue, as the second Eth washing can remove the DIPA while being easy to remove due to the high vapor pressure and immiscibility of Eth.