Artificial cave

Drilling an artificial cave, or tunnel habitat, is a concept to create room for an artificial habitat. If no usable natural caves are found an artificial tunnel can be drilled into a rock mountain. The walls of the tunnel must be stabilized and reinforced with a liner to hold in the air pressure. All surface rock formations are expected to be fractured and contain voids, so pressurization (up to 10 mT by m2) requires a pressure resistant lining. For automated construction, the usage of segmented rings or arch segments can be considered, made from compressed regolith, sintered regolith or concrete. Sprayed foam could also be used to stabilize the walls.

For example, a tunnel with a diameter of 5 meters is drilled. The Pressure resistant tunnel lining reduces the diameter to 4m. Thermal insulation using vaccum type multilayer insulation uses up a few centimeters and should ideally be installed outside the pressure lining. With such a tunnel of 1 km length, the ground area will be about 3 x 1000m or 3000m2. The volume of removed rock is 20 000 m3, while the useful final volume is 12000 m3. Clearly it would be advantageous to create a boring heat with a diameter as close as possible to the finished tunnel liner. Using three layers of hydroponic growth trays about one hectare of growth surface would be available. With typical yield of about 50 tonnes per hectare at 600 W/m2, the tunnel greenhouse could feed up to 50 people for a power demand of 6-7 MW. Being totally underground, all light must be provided with artifical lights, and mechanical cooling is required to avoid overheating and to condensate out evaporated water.

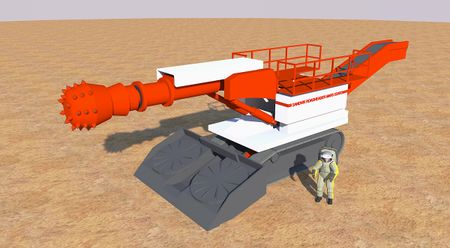

Though the drilling requires a high sophisticated digging machine this concept allows the creation of virtually unlimited room with best protection against radiation and meteorites. Once the drill is in place the process is continual and easy to be remote controlled and is, therefore, considered to be part of the unmanned setup of a whole settlement.

It is also possible to use a roadheader type of machine to dig a non circular tunnel of larger diameter that might provide a more habitable shape. Roadheaders and tunnel boring machines can reach production levels of 30m3 per hour and more, depending on a large number of variable such as stone hardness and stone quality. A single unit may be capable of digging out 60 000 m3 per year or better. This corresponds to 3 km of the 4m tunnels described.

Ideally, the excavated rock can be used to fabricate the liner, so digging into iron ore containing rock might be an interesting option. Extra material from the tunnel habitat may be used to prepare surface elements of a Mars settlement. Depending on the excavated rock, sintered regolith or Compressed Regolith Blocks might be prepared for construction purposes. Or the excavated material could simply be usef for landfill and road preparation.

The Boring Company of Elon Musk has been created to improve the performance of boring machines, and any progress made might be applicable to MArs to obtain higher productivity.

It is possible that Low gravity will be a concern for human health. In which case, a circular tunnel for a high speed railway could provide enhanced gravity. this would severely constrain colony development.

| Concepts: | Greenhouse · Settlements · Locations · General |

| Hazards: | Space Weather · Climate · General |

| Technology: | Hi-Tech · Lo-Tech · Energy · Spaceflight science · Communication · General |

| Human Considerations: | Economics · Health · Governance · Trade · Law · Social |